In my 2013 book “Mastering 21st Century Enterprise Risk Management,” I suggested “horizon scanning” as a method for monitoring risk and threats. With IoT, we have the opportunity to extend this from a series of discrete observations into continuous real-time monitoring. But let’s start with basics.

What Is IoT – Intelligent Things?

The IoT acronym for Internet of Things, like most IT acronyms, is meaningless, so it’s more recently being referred to as Intelligent Things, which is both more meaningful and allows for its expansion outside its original classification (I will come to that shortly).

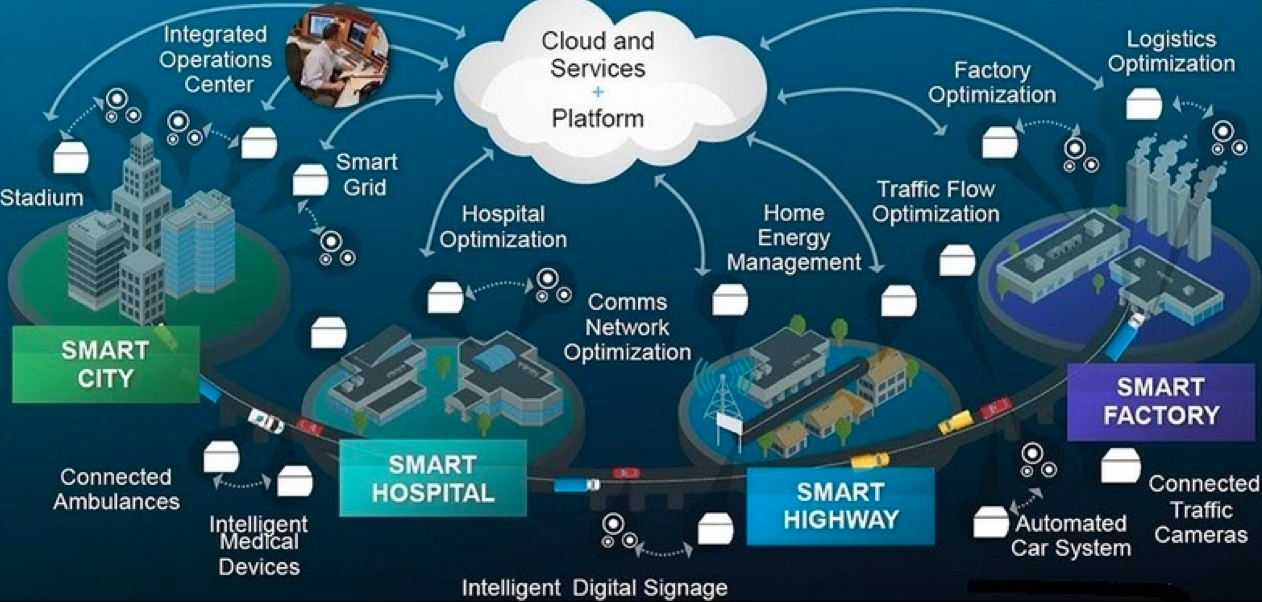

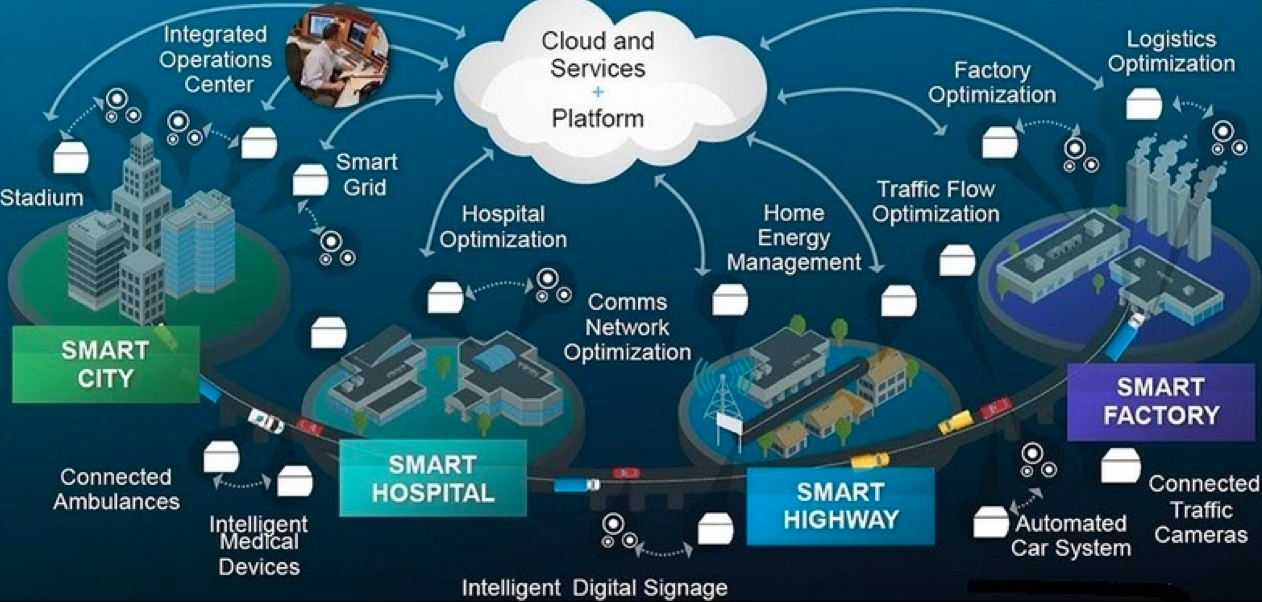

IoT technology is about collecting and processing continuous readings from wireless sensors embedded in operational equipment. These tiny electronics devices transmit their readings on heat, weight, counters, chemical content, flow rates, etc., to a nearby computer, referred to as at the “edge,” which does some basic classification and consolidation and then uploads the data to the “cloud,” where some specialist analytic system monitors those readings for anomalies.

See also: Insurance and the Internet of Things

The benefits of IoT are already well-established in the fields of equipment maintenance and material processing (see Using Predictive Analytics in Risk Management). Deloitte found that predictive maintenance can reduce the time required to plan maintenance by 20% to 50%, increase equipment uptime and availability by 10% to 20% and reduce overall maintenance costs by 5% to 10%.

Just as the advent of streaming video finally made watching movies online a reality, so streaming of data readings has produced a real paradigm shift in traditional metrics monitoring, including being able to make operational predictions up to 20 times earlier and with greater accuracy than traditional threshold-based monitoring systems.

Think about it. What if we could achieve these sorts of improvement in risk management?

Monitoring Risk Management in Real Time

The real innovation from IoT is not from the hardware technology but from the software architecture built to process streaming IoT data. Traditionally, data was collected, then processed and analyzed. Like traditional risk management, it is historic and reactive. Traditional analytics used historical data to forecast what is likely to happen based on the historically set targets and thresholds, e.g. when a sensor hits a critical reading, a release valve would open to prevent overload. Processing and energy has already been expended (lost), and the cause still needs to be rectified.

IoT technology continuously streams data and processes it in real time. Streaming analytics attempt to forecast what data is coming. Instead of initiating controls in reaction to what has happened, IoT steaming aims to alter inputs or the system to maintain optimum performance conditions. In an IoT system, inputs and processing are continually being adjusted base on the streaming analytics expectations of future readings.

This technology will have its profound and transforming effect on risk management. When it migrates from being used to measure hardware environmental factors to software-based algorithms monitoring system processes and characteristics, we will be able to assess stresses and threats, both operational and behavioral.

See also: Predictive Analytics: Now You See It….

In the 2020s, risk management will be heavily driven by KRI metrics, and as such will be a prime target for monitoring by streaming analytics. In addition to obvious environmental monitoring, streaming metrics could be used to monitor in real time staff stress and behavior, mistake (error) rates, satisfaction/complaint levels, process delays, etc. All change over time and can be adjusted in-process to prevent issues arising.

In addition to existing general-purpose IoT platforms, such as Microsoft Azure IoT, IBM Watson IoT or Amazon AWS IoT, with the advent of “serverless apps” (this technology exists now), we will see an explosion in mobile apps available from public app stores to monitor every conceivable data flow, to which you will be able to subscribe and plug in to your individual data needs. We can then finally ditch the old reactive PDCA chestnut for the ROI method of process improvement and risk mitigation (see PDCA is NOT Best Practice).

In my 2013 book “Mastering 21st Century Enterprise Risk Management,” I suggested “horizon scanning” as a method for monitoring risk and threats. With IoT, we have the opportunity to extend this from a series of discrete observations into continuous real-time monitoring. But let’s start with basics.

What Is IoT – Intelligent Things?

The IoT acronym for Internet of Things, like most IT acronyms, is meaningless, so it’s more recently being referred to as Intelligent Things, which is both more meaningful and allows for its expansion outside its original classification (I will come to that shortly).

IoT technology is about collecting and processing continuous readings from wireless sensors embedded in operational equipment. These tiny electronics devices transmit their readings on heat, weight, counters, chemical content, flow rates, etc., to a nearby computer, referred to as at the “edge,” which does some basic classification and consolidation and then uploads the data to the “cloud,” where some specialist analytic system monitors those readings for anomalies.

See also: Insurance and the Internet of Things

The benefits of IoT are already well-established in the fields of equipment maintenance and material processing (see Using Predictive Analytics in Risk Management). Deloitte found that predictive maintenance can reduce the time required to plan maintenance by 20% to 50%, increase equipment uptime and availability by 10% to 20% and reduce overall maintenance costs by 5% to 10%.

Just as the advent of streaming video finally made watching movies online a reality, so streaming of data readings has produced a real paradigm shift in traditional metrics monitoring, including being able to make operational predictions up to 20 times earlier and with greater accuracy than traditional threshold-based monitoring systems.

Think about it. What if we could achieve these sorts of improvement in risk management?

Monitoring Risk Management in Real Time

The real innovation from IoT is not from the hardware technology but from the software architecture built to process streaming IoT data. Traditionally, data was collected, then processed and analyzed. Like traditional risk management, it is historic and reactive. Traditional analytics used historical data to forecast what is likely to happen based on the historically set targets and thresholds, e.g. when a sensor hits a critical reading, a release valve would open to prevent overload. Processing and energy has already been expended (lost), and the cause still needs to be rectified.

IoT technology continuously streams data and processes it in real time. Streaming analytics attempt to forecast what data is coming. Instead of initiating controls in reaction to what has happened, IoT steaming aims to alter inputs or the system to maintain optimum performance conditions. In an IoT system, inputs and processing are continually being adjusted base on the streaming analytics expectations of future readings.

This technology will have its profound and transforming effect on risk management. When it migrates from being used to measure hardware environmental factors to software-based algorithms monitoring system processes and characteristics, we will be able to assess stresses and threats, both operational and behavioral.

See also: Predictive Analytics: Now You See It….

In the 2020s, risk management will be heavily driven by KRI metrics, and as such will be a prime target for monitoring by streaming analytics. In addition to obvious environmental monitoring, streaming metrics could be used to monitor in real time staff stress and behavior, mistake (error) rates, satisfaction/complaint levels, process delays, etc. All change over time and can be adjusted in-process to prevent issues arising.

In addition to existing general-purpose IoT platforms, such as Microsoft Azure IoT, IBM Watson IoT or Amazon AWS IoT, with the advent of “serverless apps” (this technology exists now), we will see an explosion in mobile apps available from public app stores to monitor every conceivable data flow, to which you will be able to subscribe and plug in to your individual data needs. We can then finally ditch the old reactive PDCA chestnut for the ROI method of process improvement and risk mitigation (see PDCA is NOT Best Practice).Using IoT to Monitor Risk in Real Time

Streaming of data readings allows operational predictions 20 times earlier. What if risk management saw similar improvements?

In my 2013 book “Mastering 21st Century Enterprise Risk Management,” I suggested “horizon scanning” as a method for monitoring risk and threats. With IoT, we have the opportunity to extend this from a series of discrete observations into continuous real-time monitoring. But let’s start with basics.

What Is IoT – Intelligent Things?

The IoT acronym for Internet of Things, like most IT acronyms, is meaningless, so it’s more recently being referred to as Intelligent Things, which is both more meaningful and allows for its expansion outside its original classification (I will come to that shortly).

IoT technology is about collecting and processing continuous readings from wireless sensors embedded in operational equipment. These tiny electronics devices transmit their readings on heat, weight, counters, chemical content, flow rates, etc., to a nearby computer, referred to as at the “edge,” which does some basic classification and consolidation and then uploads the data to the “cloud,” where some specialist analytic system monitors those readings for anomalies.

See also: Insurance and the Internet of Things

The benefits of IoT are already well-established in the fields of equipment maintenance and material processing (see Using Predictive Analytics in Risk Management). Deloitte found that predictive maintenance can reduce the time required to plan maintenance by 20% to 50%, increase equipment uptime and availability by 10% to 20% and reduce overall maintenance costs by 5% to 10%.

Just as the advent of streaming video finally made watching movies online a reality, so streaming of data readings has produced a real paradigm shift in traditional metrics monitoring, including being able to make operational predictions up to 20 times earlier and with greater accuracy than traditional threshold-based monitoring systems.

Think about it. What if we could achieve these sorts of improvement in risk management?

Monitoring Risk Management in Real Time

The real innovation from IoT is not from the hardware technology but from the software architecture built to process streaming IoT data. Traditionally, data was collected, then processed and analyzed. Like traditional risk management, it is historic and reactive. Traditional analytics used historical data to forecast what is likely to happen based on the historically set targets and thresholds, e.g. when a sensor hits a critical reading, a release valve would open to prevent overload. Processing and energy has already been expended (lost), and the cause still needs to be rectified.

IoT technology continuously streams data and processes it in real time. Streaming analytics attempt to forecast what data is coming. Instead of initiating controls in reaction to what has happened, IoT steaming aims to alter inputs or the system to maintain optimum performance conditions. In an IoT system, inputs and processing are continually being adjusted base on the streaming analytics expectations of future readings.

This technology will have its profound and transforming effect on risk management. When it migrates from being used to measure hardware environmental factors to software-based algorithms monitoring system processes and characteristics, we will be able to assess stresses and threats, both operational and behavioral.

See also: Predictive Analytics: Now You See It….

In the 2020s, risk management will be heavily driven by KRI metrics, and as such will be a prime target for monitoring by streaming analytics. In addition to obvious environmental monitoring, streaming metrics could be used to monitor in real time staff stress and behavior, mistake (error) rates, satisfaction/complaint levels, process delays, etc. All change over time and can be adjusted in-process to prevent issues arising.

In addition to existing general-purpose IoT platforms, such as Microsoft Azure IoT, IBM Watson IoT or Amazon AWS IoT, with the advent of “serverless apps” (this technology exists now), we will see an explosion in mobile apps available from public app stores to monitor every conceivable data flow, to which you will be able to subscribe and plug in to your individual data needs. We can then finally ditch the old reactive PDCA chestnut for the ROI method of process improvement and risk mitigation (see PDCA is NOT Best Practice).

In my 2013 book “Mastering 21st Century Enterprise Risk Management,” I suggested “horizon scanning” as a method for monitoring risk and threats. With IoT, we have the opportunity to extend this from a series of discrete observations into continuous real-time monitoring. But let’s start with basics.

What Is IoT – Intelligent Things?

The IoT acronym for Internet of Things, like most IT acronyms, is meaningless, so it’s more recently being referred to as Intelligent Things, which is both more meaningful and allows for its expansion outside its original classification (I will come to that shortly).

IoT technology is about collecting and processing continuous readings from wireless sensors embedded in operational equipment. These tiny electronics devices transmit their readings on heat, weight, counters, chemical content, flow rates, etc., to a nearby computer, referred to as at the “edge,” which does some basic classification and consolidation and then uploads the data to the “cloud,” where some specialist analytic system monitors those readings for anomalies.

See also: Insurance and the Internet of Things

The benefits of IoT are already well-established in the fields of equipment maintenance and material processing (see Using Predictive Analytics in Risk Management). Deloitte found that predictive maintenance can reduce the time required to plan maintenance by 20% to 50%, increase equipment uptime and availability by 10% to 20% and reduce overall maintenance costs by 5% to 10%.

Just as the advent of streaming video finally made watching movies online a reality, so streaming of data readings has produced a real paradigm shift in traditional metrics monitoring, including being able to make operational predictions up to 20 times earlier and with greater accuracy than traditional threshold-based monitoring systems.

Think about it. What if we could achieve these sorts of improvement in risk management?

Monitoring Risk Management in Real Time

The real innovation from IoT is not from the hardware technology but from the software architecture built to process streaming IoT data. Traditionally, data was collected, then processed and analyzed. Like traditional risk management, it is historic and reactive. Traditional analytics used historical data to forecast what is likely to happen based on the historically set targets and thresholds, e.g. when a sensor hits a critical reading, a release valve would open to prevent overload. Processing and energy has already been expended (lost), and the cause still needs to be rectified.

IoT technology continuously streams data and processes it in real time. Streaming analytics attempt to forecast what data is coming. Instead of initiating controls in reaction to what has happened, IoT steaming aims to alter inputs or the system to maintain optimum performance conditions. In an IoT system, inputs and processing are continually being adjusted base on the streaming analytics expectations of future readings.

This technology will have its profound and transforming effect on risk management. When it migrates from being used to measure hardware environmental factors to software-based algorithms monitoring system processes and characteristics, we will be able to assess stresses and threats, both operational and behavioral.

See also: Predictive Analytics: Now You See It….

In the 2020s, risk management will be heavily driven by KRI metrics, and as such will be a prime target for monitoring by streaming analytics. In addition to obvious environmental monitoring, streaming metrics could be used to monitor in real time staff stress and behavior, mistake (error) rates, satisfaction/complaint levels, process delays, etc. All change over time and can be adjusted in-process to prevent issues arising.

In addition to existing general-purpose IoT platforms, such as Microsoft Azure IoT, IBM Watson IoT or Amazon AWS IoT, with the advent of “serverless apps” (this technology exists now), we will see an explosion in mobile apps available from public app stores to monitor every conceivable data flow, to which you will be able to subscribe and plug in to your individual data needs. We can then finally ditch the old reactive PDCA chestnut for the ROI method of process improvement and risk mitigation (see PDCA is NOT Best Practice).